Business Overview

Metal 3D Printer (Additive Manufacturing) Contracting Business

Contract Modeling with Metal 3D Printer (Additive Manufacturing)

Environment and Technology :

Innovation from Subtraction to Addition

TKE's Metal 3D Printer (Additive Manufacturing) Technology realizes your "Creation".

TKE's 3D Printer (Additive Manufacturing) Technology creates the products

that customers want in every manufacturing fields.

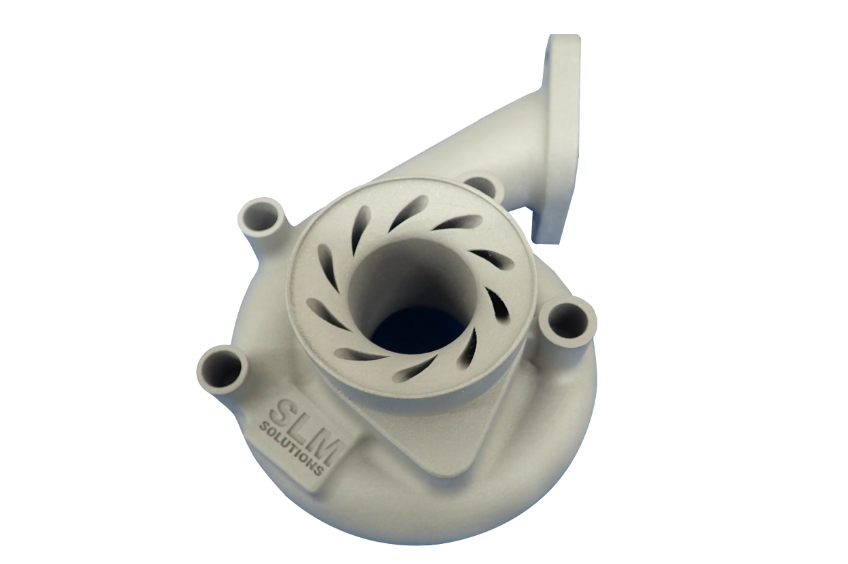

Facility Introduction: Metal 3D Printer (Additive Manufacturing) Model: SLM280PS

-

Name of Manufacturer

SLM Solutions GmbH (Germany)

-

Modeling Method

SLM (Selective Laser Melting) Method: Powder Bed/Laser Melting

-

Size of Model

Width(280) x Length(280) x Hight (365)mm

-

Laser Output

700W Infrared Laser x 2

-

Variable layer thickness

20~100μm

-

Machine Dimension

Width(4,150) x Length(2,900) x Hight (2,500)mm

-

Automatic Sieving System (Automatic Sieving Machine)

-

Bidirectional recoater (recoating) system

Compatible materials

Copper, aluminum, stainless steel, inconel, mold steel, etc.

Metal 3D printer (Additive Manufacturing) : 3 features

-

01

Available for Wide Range of Copper Products Modeling

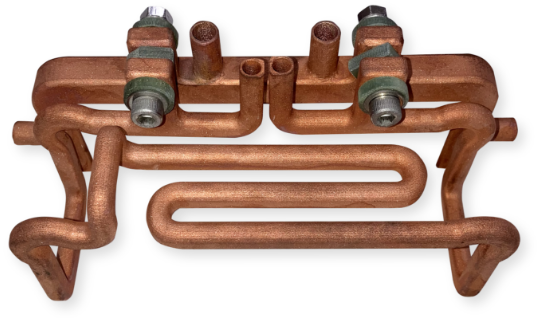

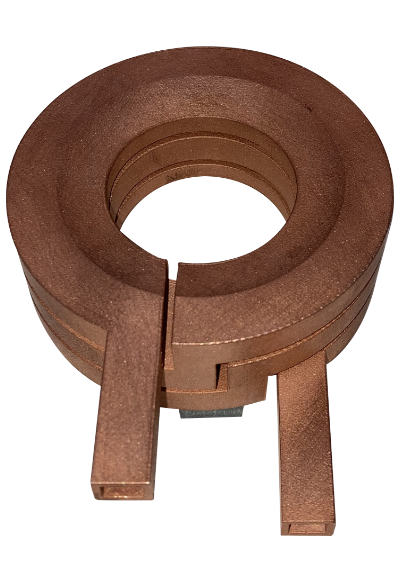

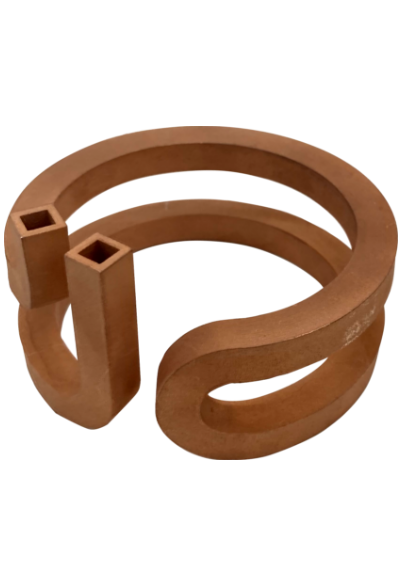

It is now possible to model copper products, which was difficult with conventional 3D printers (Additive Manufacturing) . TKE handles a wide range of copper products such as induction hardening coil, heat exchanger parts, and electric equipment parts.

-

02

Possible to Metal Modeling in Complex Designs

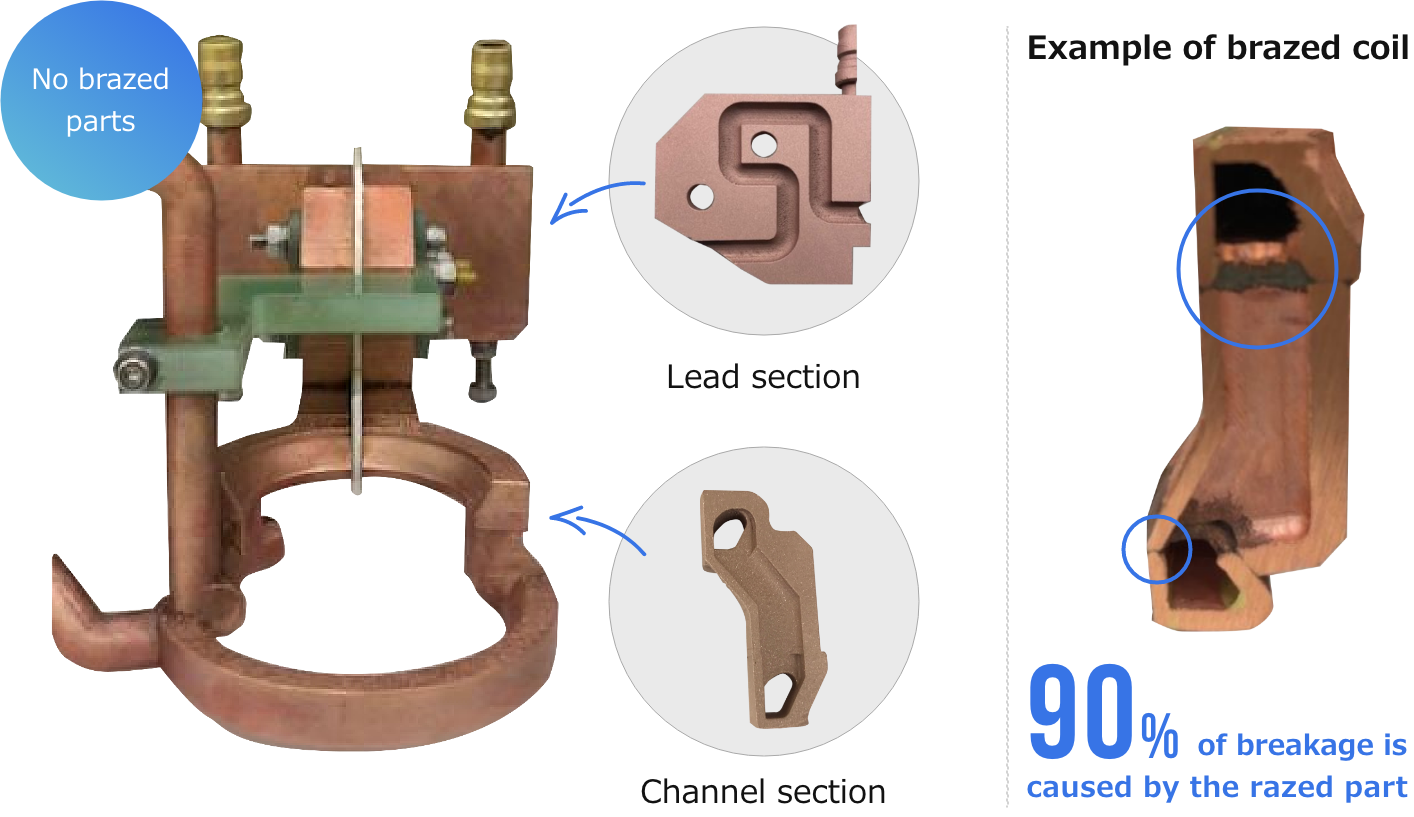

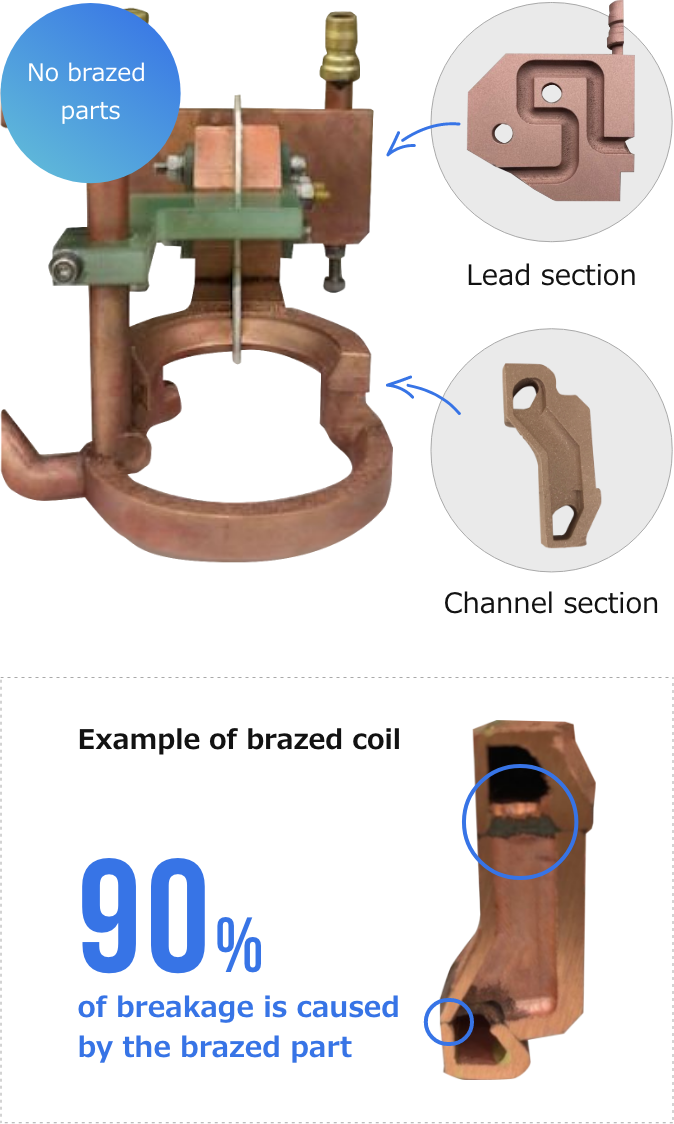

Make possible for complex design that used to impossible so that expanding the possibility of free designing. The induction hardening coil has eliminated brazed parts and making it possible to design more efficient cooling water channel shapes.

-

03

Sample Production with

Lower Cost and Higher Quality

than Casting and ForgingUsing not only copper but also any other compatible materials, we handle modeling prototypes before mass production.

TKE POINT

TKE specializes producing the induction hardening coils!

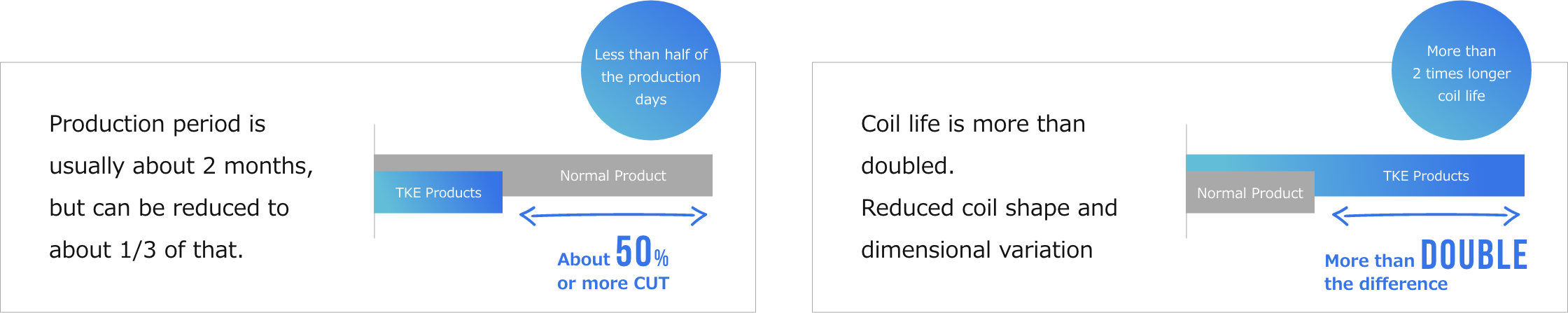

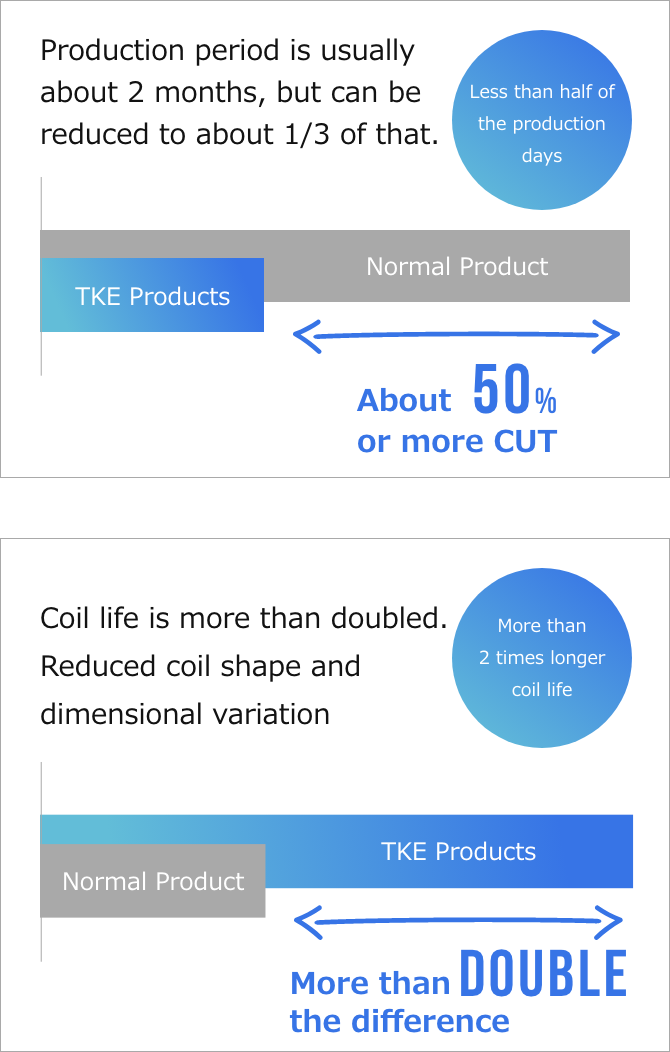

By manufacturing integrated model with Metal 3D Printer (Additive Manufacturing), the brazed part are eliminated which accounts for 90% of coil breakage causes. As a result, the coil life is extended, the complex waterway can be configured, and the quality is stable and improved.

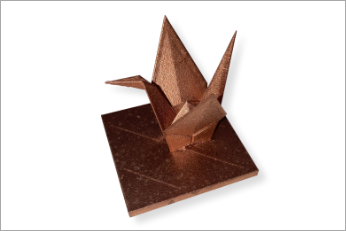

Examples of 3D Printer (Additive Manufacturing) Fabricated Products

Various objects can be modeled.

In particular, by the free designing of induction hardening coils and heat sinks, can be configured complex shape as customer’s needs and used at the manufacturing sites.

-

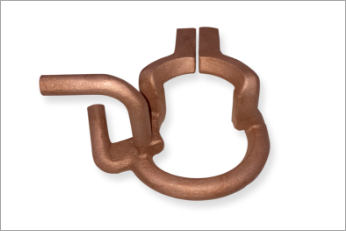

Induction Hardening Coil ①

-

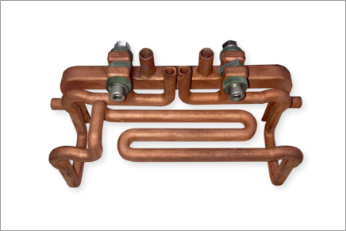

Induction Hardening Coil ②

-

Induction Hardening Coil ③

-

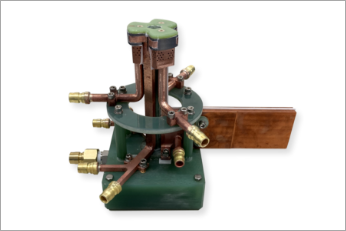

Direct Copper Modeling on Stainless Steel

Copper products were modeled directly on machined stainless steel material.

-

Object ①

-

Object ②