October 31,2023

TKE received the 2023 "Super" Manufacturing Parts Award which is rated as one of the best and hosted by MONOZUKURI Nihon Conference and The Nikkan Kogyo Shimbun.

< Winning Product >

「Brazing free made induction heating coils (AM coil®)」

<Product Outline>

It is an induction heating coil used for induction hardening that developed and put into practical use as Brazing free Induction heating coil(AM coil®) with design made used of CAE analysis and made by 3D printing.

-

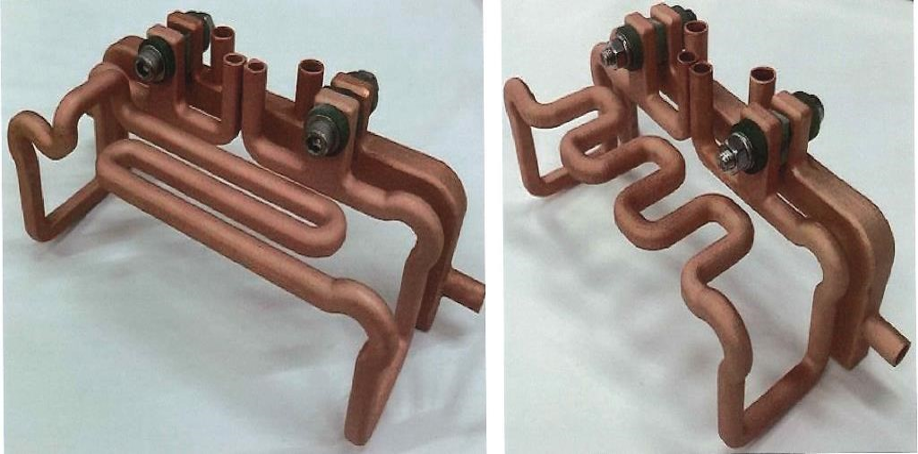

Outer diameter stationary quenching coil

-

Inner surface quenching coil

-

Flat surface quenching coil

-

Single-shot quenching coil

< Product Feature >

In general, designing induction heating coils needs experiences and assembling them with machined copper parts by “brazing" takes time , and in addition, it also takes a lot of time and effort to train staffs. AM coil® is utilizing CAE analysis in designing and manufacturing by 3D printing, and which leads to shorten manufacturing process. Reproducibility and durability are also improved substantially by digitalization. In addition, a high degree of efficiency coil production has become possible by the degree of free design.

-

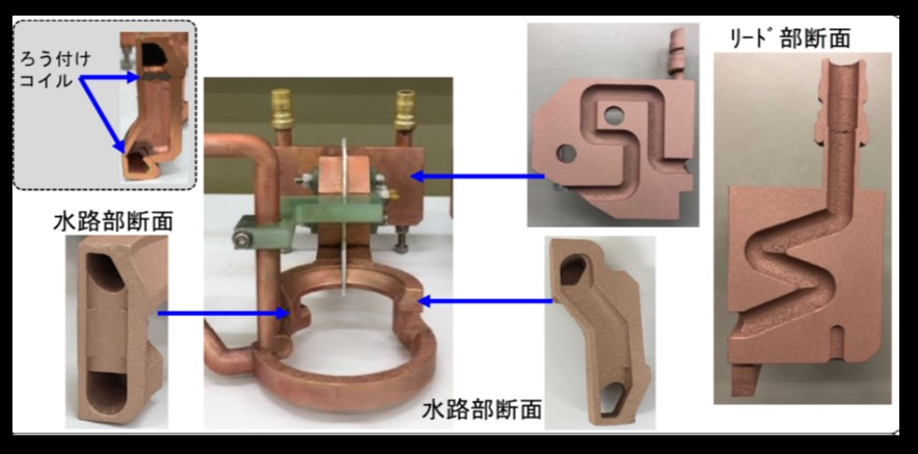

AM coil’s inside : built without jointing

-

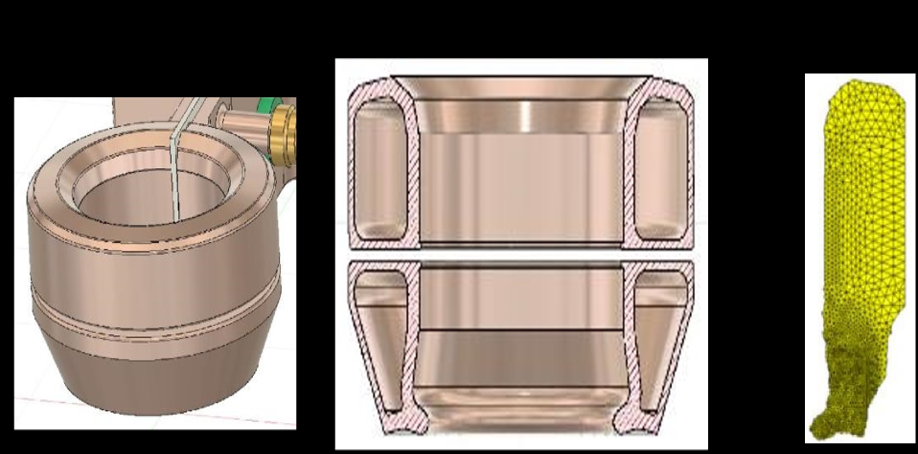

3D-CAD realizes the coil shape which is resulted from Topology Optimization

< Product Quality>

|

①Stabilize and improve coil life |

In comparison with conventional brazing coil lifetime, the lifetime is several times longer. |

|

②Shortening the coil production period |

Brazing coil production time was 1-3 months but it’s shorten to 9 days after data processing is completed. |

| ③Coil optimization design |

By the degree of free design is improved and no longer have to do machining, designing as you want became possible. |

| ④Combination with CAE (Practical Use of Topology Optimization) | Simulation is performed to confirm whether the coil would satisfy the heat treatment specification with the coil shape concerned after coil designing. In addition, we input product shape/dimensions and heat treatment specifications into Topology Optimization analysis, and by 3D printing, manufactured the coil with the design derived from analysis, then verified that Topology Optimization can be used practically. |